In the marine sector, the primary objective is to meet the customer’s specifications to ensure product efficiency and quality. Reart’s role is to define the component to be proposed based on the scope of the project.

Some of Reart’s activities focus on vessels such as medium-sized and small luxury yachts, where resistors are installed for water heaters and boilers. Larger vessels require more powerful three-phase resistors, while smaller ones use standard water heater resistors:

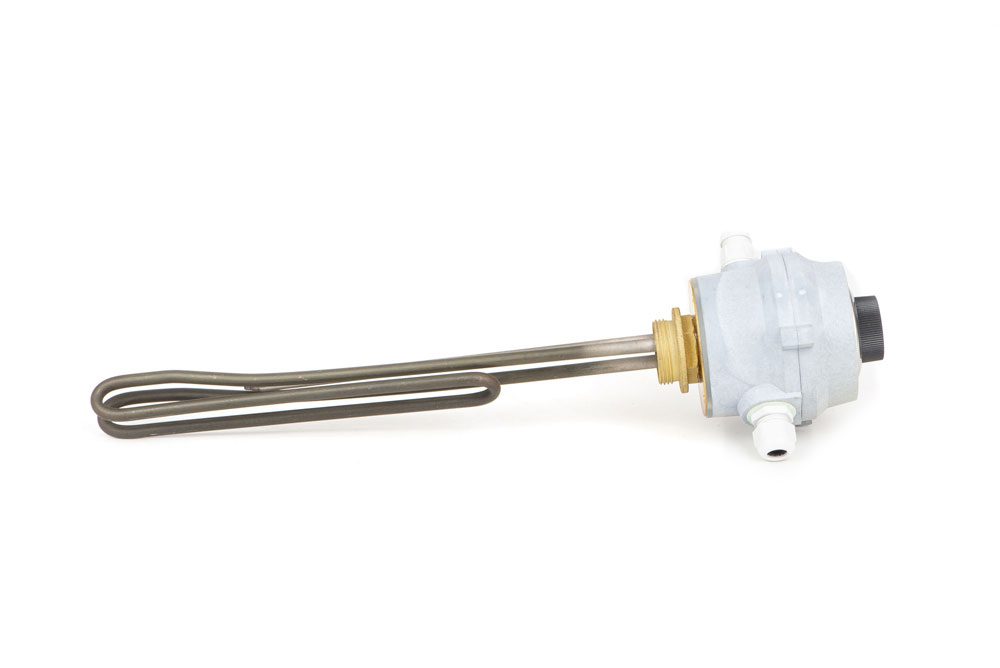

In water heating systems that concern large vessels such as cruise ships, yachts, and operational ships, immersion electric resistors play a key role. Reart manufactures threaded or flange-mounted electric heaters that are inserted into storage tanks to heat water treated by various systems on board (reverse osmosis, softener, and filters).

On board yachts and medium-small vessels, the resistor is inserted into boilers for the production of hot water primarily for sanitary use. On large cruise ships, three-phase resistors are essential components for heating water that feeds pools, kitchens, and passenger cabins.

For comfort and well-being on board, such as in services with hot tubs, special threaded immersion electric heaters are used to maintain the water temperature in recirculation circuits.

In other divisions of the marine sector, such as those related to operational support vessels for underwater operations, electric heat exchangers are used.

These support the working conditions of divers operating at very low depths by heating saltwater directly taken from the sea. For these applications, noble materials and specific metal alloys are used, such as Incoloy 800, titanium, stainless steel 316L, and Hastelloy 600 or 800, to withstand corrosive conditions.

VIA PINEROLO, 20/2

10060 FROSSASCO (TO) ITALY

PHONE +39 0121.35.29.77

FAX +39 0121.35.29.68

Ufficio Vendite sales@recogroup.it

Ufficio Acquisti acquisti@recogroup.it

Amministrazione amministrazione@recogroup.it

P.IVA 03948060011

VIA PINEROLO, 20/2

10060 FROSSASCO (TO) ITALY

PHONE +39 0121.35.29.77

FAX +39 0121.35.29.68

Ufficio Vendite sales@recogroup.it

Ufficio Acquisti acquisti@recogroup.it

Amministrazione amministrazione@recogroup.it

P.IVA 04727180012

Copyright © 2023 Reco Group – registration in the commercial register Torino n. 03948060011 – Privacy Policy | Cookie Policy | Review consent cookie