An important sector in terms of plant engineering is the Plastic and Rubber molding Industry, which employs various models of electric heaters and air heaters for small, medium, and high-quality plants with advanced technology.

Electric resistances heaters are used in rubber molding, plastic injection, extrusion, thermoforming, and temperature control systems to control and regulate the temperature of the process fluid (water or oil).

Reart division is committed to providing effective and customized heating solutions for plastic and rubber molding: the technical team knows how crucial it is to maintain precise and controlled temperatures to ensure the quality of the final product.

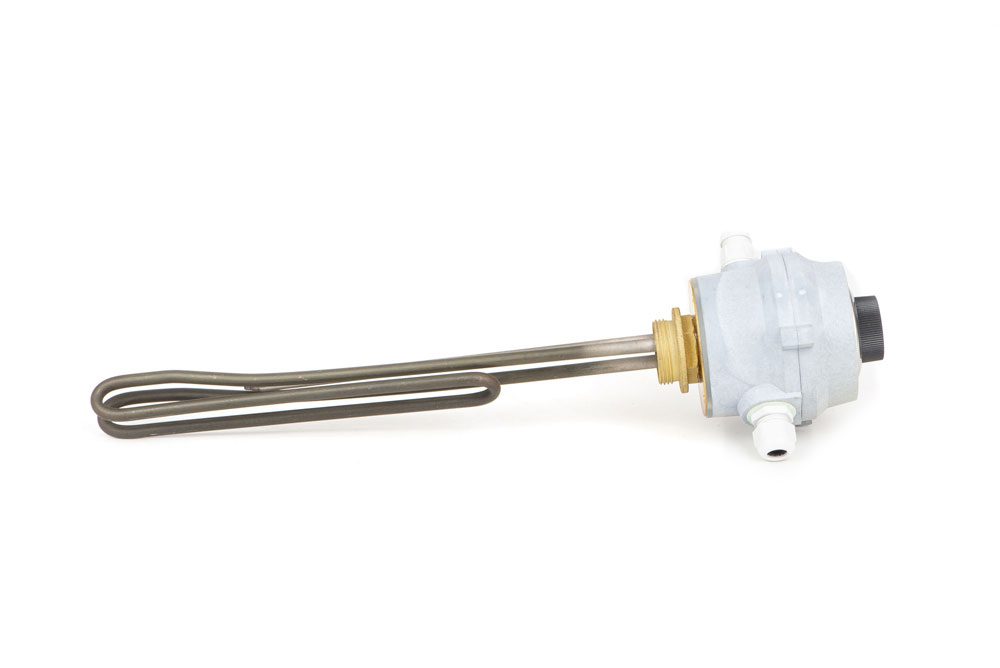

Reart’s threaded and flanged immersion electric heaters are specifically designed to meet the specific needs of individual molding processes. Based on their extensive experience in the industry, Reart is able to collaborate and understand the specific heating requirements.

Careful analysis is carried out on the process conditions, including:

Based on this information, the most suitable electric heaters are sized and designed to achieve optimal performance.

Reart’s threaded immersion electric heaters are designed to be directly installed in the process tank or reservoir, ensuring direct and uniform contact with the fluid. This ensures efficient and rapid heating, allowing precise and reliable achievement and maintenance of desired temperatures.

For applications that require higher mechanical resistance and better heat distribution, Reart also offers flanged electric heaters. These heaters are mounted on specific flanges that can handle high temperatures and provide uniform heat distribution over the entire contact surface.

Reart’s priority is to provide tailor-made solutions that fully meet your needs. In addition to selecting the appropriate heater, the technical team can support you in the design and integration of the heaters into your plant. A comprehensive service is provided, from initial consultation to commissioning and after-sales support.

By choosing Reart’s threaded and flanged immersion electric heaters, you can rely on high-quality, reliable products that comply with safety standards.

Reart’s experience in the Plastic Molding Industry has allowed them to develop innovative and efficient solutions that will improve the efficiency of your process and achieve optimal results.

VIA PINEROLO, 20/2

10060 FROSSASCO (TO) ITALY

PHONE +39 0121.35.29.77

FAX +39 0121.35.29.68

Ufficio Vendite sales@recogroup.it

Ufficio Acquisti acquisti@recogroup.it

Amministrazione amministrazione@recogroup.it

P.IVA 03948060011

VIA PINEROLO, 20/2

10060 FROSSASCO (TO) ITALY

PHONE +39 0121.35.29.77

FAX +39 0121.35.29.68

Ufficio Vendite sales@recogroup.it

Ufficio Acquisti acquisti@recogroup.it

Amministrazione amministrazione@recogroup.it

P.IVA 04727180012

Copyright © 2023 Reco Group – registration in the commercial register Torino n. 03948060011 – Privacy Policy | Cookie Policy | Review consent cookie