Galvanization technology is a technique primarily used in the industrial sector to coat a non-precious metal with a thin layer of a more precious, noble, or passivable metal through electrolytic deposition. This process involves various treatments that use aqueous solutions containing metal salts, acids, bases, and specific additives within sequentially aligned tanks.

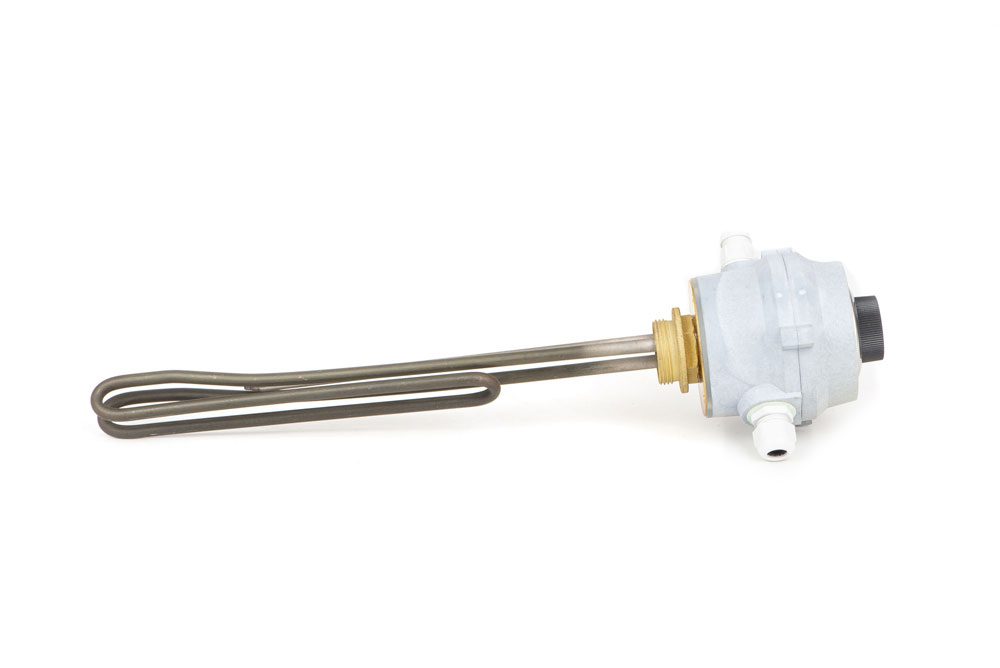

These surface chemical treatments are applied to give the material a particular final aesthetic. To ensure the effectiveness of the electrolytic treatment, the galvanic bath requires specific thermal characteristics: Reart provides products specifically designed to maintain solutions at a controlled temperature using electric resistances, typically between 20 and 40 °C, using special materials and technologies, as tubular electric heaters are not suitable for these cases.

Reart’s electric resistances for galvanization are used in various applications, including nickel plating, chrome plating, copper plating, precious metals plating, electropolishing, pickling, and passivation.

Based on customer requirements, Reart can produce titanium electric resistances, used in special baths for the treatment of precious metals such as gold. In the case of pickling and passivation, single-tube heaters or shaped electric resistances are used.

Both small and medium-sized companies perform various types of galvanic baths using single-tube heaters made of different materials. For particularly large tanks, custom-made resistances are created.

In special cases, even Reart’s electric resistances themselves undergo galvanic treatments.

VIA PINEROLO, 20/2

10060 FROSSASCO (TO) ITALY

PHONE +39 0121.35.29.77

FAX +39 0121.35.29.68

Ufficio Vendite sales@recogroup.it

Ufficio Acquisti acquisti@recogroup.it

Amministrazione amministrazione@recogroup.it

P.IVA 03948060011

VIA PINEROLO, 20/2

10060 FROSSASCO (TO) ITALY

PHONE +39 0121.35.29.77

FAX +39 0121.35.29.68

Ufficio Vendite sales@recogroup.it

Ufficio Acquisti acquisti@recogroup.it

Amministrazione amministrazione@recogroup.it

P.IVA 04727180012

Copyright © 2023 Reco Group – registration in the commercial register Torino n. 03948060011 – Privacy Policy | Cookie Policy | Review consent cookie