Reart has studied and developed new solutions and models of heat exchangers and electric batteries applicable to the emerging market of renewable energy, to meet the demand for energy recovery from renewable sources in geothermal power plants, wind farms, and heat flows from the underground.

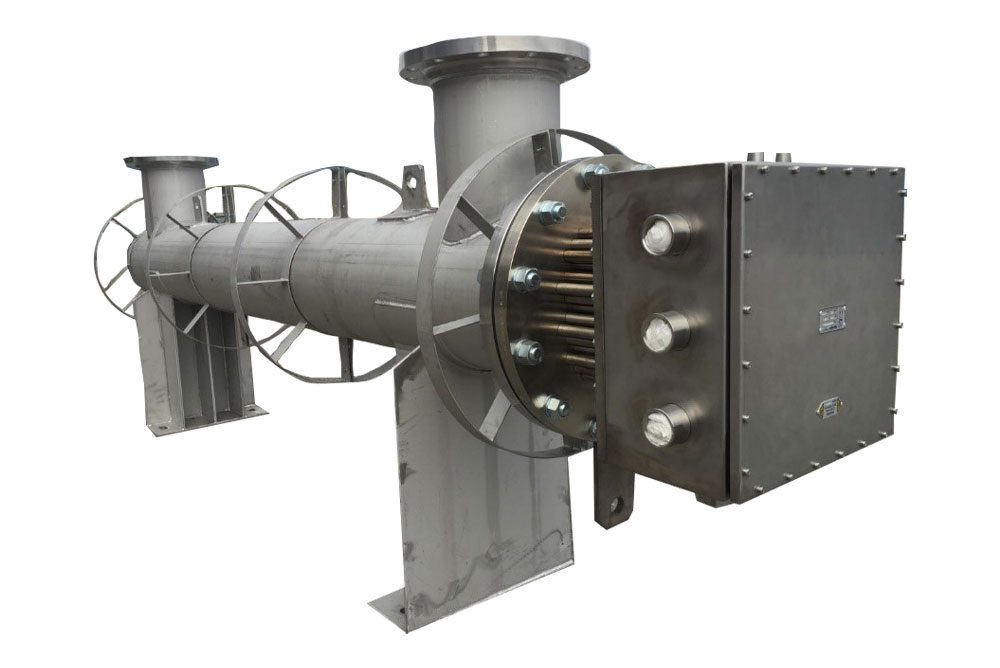

Geothermal power plants harness the heat generated from the Earth and convert it into electricity through the systems that make up the geothermal plant. The gas, consisting of a mixture of water vapor and non-condensable gases in varying ratios, reaches a temperature of approximately 50°C at the surface. An electric heat exchanger then heats the outgoing gas to a temperature of around 350°C. This expanding gas, acting on the turbine, generates mechanical force that transforms it into electrical energy through an alternator and a transformer.

Batteries and heat exchangers used in wind farms, on the other hand, are employed as a braking load or for dissipating excessive current generated by the plant. One of Reart’s main areas of intervention specifically concerns wind turbine blades, which, when in operation, generate large amounts of current that need to be discharged between the primary circuit and the secondary circuit before generating electricity to be distributed to the grid.

In some cases, to prevent the plant from stalling, it is necessary to dissipate this excess energy. To address this challenge, electric batteries are used to absorb the excess current and generate heat, which is subsequently dissipated into the environment.

Reart’s standard and customized electric heat exchangers and duct heaters are designed to ensure efficient heat transfer between the primary and secondary electrical circuits of wind turbine blades. With their experience and expertise in the field, Reart offers solutions that balance the frequency within the system, contributing to the optimization of wind farm performance.

Furthermore, Reart’s customized batteries are designed to ensure optimal operation of the wind farm and to avoid wastage of electrical energy.

Reart is committed to providing innovative and adaptable solutions to meet the specific needs of the energy sector, in order to deliver reliable performance, energy efficiency, and greater sustainability to geothermal power plants, wind farms, and other energy applications

Reart’s technical team is ready to offer advanced solutions in the renewable energy sector, contributing to the transition towards a sustainable energy system and the efficient use of renewable resources.

Reart produce resistenze elettriche tubolari lisce ed alettate a seconda delle necessità del cliente. Le resistenze elettriche sono progettate e dimensionate in base alle dimensioni utili e alle condizioni di processo.

Per Forni Industriali si intendono quelle tipologie di forni da utilizzarsi per le diverse applicazioni nei processi di trattamento termico, quali: ricottura, essiccazione, rinvenimento, ecc…

La temperatura massima ammissibile delle resistenze elettriche è 750°C di riscaldamento del gas di processo.

Le resistenze elettriche per forni industriali possono avere diametro 10 o 15 mm, essere di materiale inox oppure incoloy 800, con raccordi saldati o aggraffati in ottone oppure in inox.

VIA PINEROLO, 20/2

10060 FROSSASCO (TO) ITALY

PHONE +39 0121.35.29.77

FAX +39 0121.35.29.68

Ufficio Vendite sales@recogroup.it

Ufficio Acquisti acquisti@recogroup.it

Amministrazione amministrazione@recogroup.it

P.IVA 03948060011

VIA PINEROLO, 20/2

10060 FROSSASCO (TO) ITALY

PHONE +39 0121.35.29.77

FAX +39 0121.35.29.68

Ufficio Vendite sales@recogroup.it

Ufficio Acquisti acquisti@recogroup.it

Amministrazione amministrazione@recogroup.it

P.IVA 04727180012

Copyright © 2023 Reco Group – registration in the commercial register Torino n. 03948060011 – Privacy Policy | Cookie Policy | Review consent cookie