Reart produces flange-mounted electric heaters for heating liquids and gases of all kinds for the civil, plant and industrial sectors. The flanged heaters are studied and designed to fix the electric heater to the process to be heated by means of a special connection flange which is defined according to the UNI or ANSI 16.5 standards. The process connection flanges can also be designed and built according to the customer’s specifications or requests.

This type of heater is used for heating fluids in:

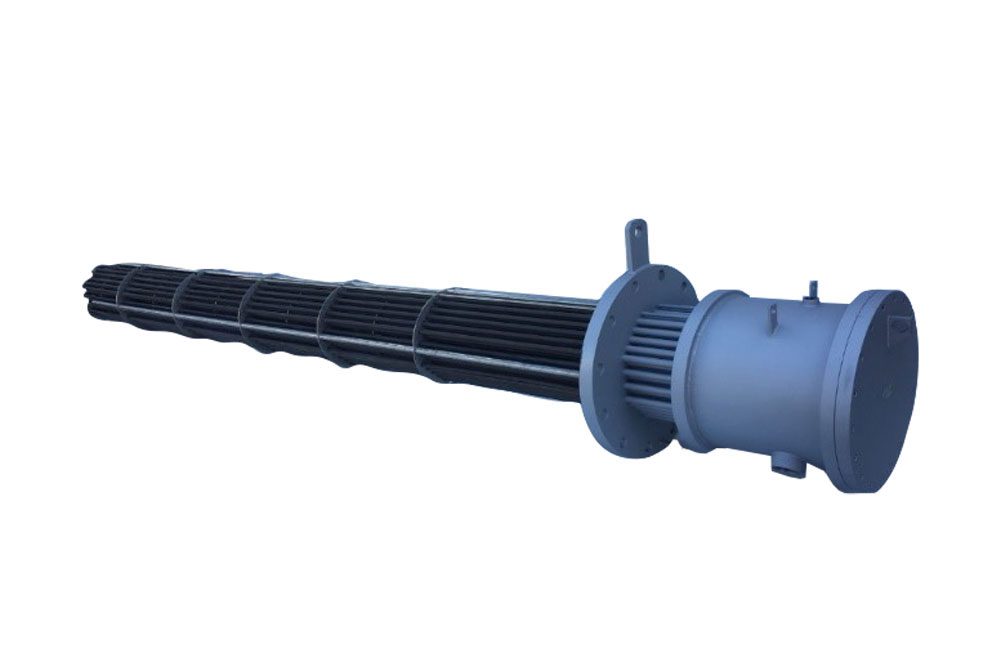

Electric flange immersion heaters are suitable for heating all non-corrosive process fluids. They consist of one or more U-bent or eyelet-bent heating elements welded to the main connection flange by TIG welding or brazing, complete with electrical connections, safety devices and relative protective case of the electrical connections.

All the heating elements welded on the main flange of the heater are tested through hydraulic tests at well-defined pressures according to the design conditions indicated by the customer.

Thanks to the hydraulic test performed by Reart on the welded heater, it is possible to guarantee the tightness of the welds of the heating elements to the flange, declaring this test in the final test certificate issued with the product by Reart.

The electrically armoured flange heaters essentially consist of:

Heater connection flange to the process

Electrical heating beam with dimensions and materials depending on the process fluid

Cooling and heat exchange baffles between electrical beam and fluid

Electric protection unit and head

Thermal control and safety sensors system and heater.

The connection flange of the electric heater is defined in agreement with the customer already in the offer phase, so that the heater can be dimensioned according to the process data.

In addition to the functional data requested by the customer, the design for this type of heater is carried out by considering and evaluating dimensional (usable space), physical, chemical and thermodynamic characteristics of the fluid to be heated, for a precise and accurate choice of heater sizing and construction materials.

The electrical power installed on electric flange heaters can vary up to thousands of kW with the help of types and settings according to customer specifications and Reart engineering.

In general, the following design parameters can be used as a reference for the dimensioning of electric flange heaters

Flanges up to 48″ according to ANSI B 16.5 specifications in carbon steels, stainless steels and nickel alloys.

Diameter of heating elements forming in tube bundle 8.5, 10 and 15 mm;

Material of heating elements in carbon steel, stainless steel 304-321 316(L), or considerably more noble alloys such as Incoloy 800 or 825,Titanium or Copper.

Degree of protection of the electrical enclosures of the heaters IP40, IP55, IP65, IP66;

Installed electrical power of up to 2MW per individual heater.

Maximum immersion length of electrical bundle approx. 3 metres.

All flange-mounted electric heaters can be fitted with thermal sensors such as thermostats and/or thermocouples or resistance thermometers (PT100) to safeguard the system and the heater itself in the event of abnormal or unforeseen situations on the system.

Electric flange heaters are also customised to customer specifications.

VIA PINEROLO, 20/2

10060 FROSSASCO (TO) ITALY

PHONE +39 0121.35.29.77

FAX +39 0121.35.29.68

Ufficio Vendite sales@recogroup.it

Ufficio Acquisti acquisti@recogroup.it

Amministrazione amministrazione@recogroup.it

P.IVA 03948060011

VIA PINEROLO, 20/2

10060 FROSSASCO (TO) ITALY

PHONE +39 0121.35.29.77

FAX +39 0121.35.29.68

Ufficio Vendite sales@recogroup.it

Ufficio Acquisti acquisti@recogroup.it

Amministrazione amministrazione@recogroup.it

P.IVA 04727180012

Copyright © 2023 Reco Group – registration in the commercial register Torino n. 03948060011 – Privacy Policy | Cookie Policy | Review consent cookie